Engines

Gears

Anti-freeze/Coolants

Investigative, Deposits,

Filters & components

Hydraulic,

Compressors,

Turbines

Transformer

/Electrical

SCR/DEF Adblue

Greased

Bearings

Elastomers

Thermal Oils

Cutting oils

Diesels

Please select a sample/machinery type to find out more about the testing we offer.

Engine Coolants

Engine coolant analysis can help detect faults such as:

Inadequate cooling/overheating

Contamination with screenwash, fuel, oil, tap water or adblue

System corrosion or cavitation

Incorrectly concentrated coolant

High oil consumption

Coolant chemical breakdown

Combustion Gas Leaks

Electrical ground problems

As Standard all Analysis includes:

In depth & personalised human diagnostics

Our greenest low paper & reused plastic packaging

Next Working day turnarounds.

Our cog-marked bottle designed to be robust and resistant.

Unlimited access to LearnOilAnalysis.com resources

Online Access & Unlimited Training on LubeWear.com portal

Fast & Error Free Electronic Pre-Registration

Lab telephoning you for urgent/critical results

Continuous improvements to the service from your feedback

UK Return Postage to lab

Lab Testing Includes:

Appearance, Clarity & Colour

Anti-corrosion additive elements

Contamination Elements

Water Hardness as CaCO3

Molybdates

Phosphates

pH

Glycol %

Freezing Point degC

Tap/Salt Water contamination

Oil/fuel contamination

LubeWear Aqueous True Wear Corrosion Metal Analysis

OAL Vapour and Liquid Phase Corrosion Inhibition

Ferrous ppm Total Dissolved Solids

Water Turbidity. NitratesNitrites

Iron Type - Wear vs Corrosion

Adblue Contamination Glycol type e.g. Ethylene / Propylene.

Conductivity Screen wash Contamination

Oxidation Reduction Potential (ORPs). Boiling Point

Legend:

= Standard Test.

Exclusive to OAL

= Ref oil required.

= Diamond Upgrade

Example ReportBuy Me

Engine Oils

Engine oil analysis can help detect faults such as:

Fuel leaks

Air intake/filter problems

Coolant leaks

Worn rings

Over used, overheated or over sooted oil

As Standard all Analysis includes:

In depth & personalised human diagnostics

Our greenest low paper & reused plastic packaging

Next Working day turnarounds.

Our cog-marked bottle designed to be robust and resistant.

Unlimited access to LearnOilAnalysis.com resources

Online Access & Unlimited Training on LubeWear.com portal

Fast & Error Free Electronic Pre-Registration

Lab telephoning you for urgent/critical results

Continuous improvements to the service from your feedback

UK Return Postage to lab

Lab Testing Includes:

Viscosity @ 40C

Additive Elements

Contamination Elements

Hot Surface Open Flash Point

Standard ICP Wear Elements

LubeWear True Wear Metal Analysis

Remaining Anti-wear additives

Base Number Depletion

Oxidation, Nitration & Sulphation

Anti-freeze / Glycol %

Soot %

Diesel Fuel Dilution %

Dissolved Water (ppm)

Free Water %

Viscosity @ 100C. Viscosity Index Ferrous ppm

Sulpahted Ash (SAPS). Initial pH Acid Number

Iron Type - Wear vs Corrosion Flash Closed + Open & Fire Point.

Biodiesel Dilution OAL condition Index Asphaltenes

CAT Fines. Chlorine Density Pour Point Ferrography

Anti-oxidant additives Dispersancy Oxidation stability (RPVOT)

Oil Coking characteristics

Legend:

= Standard Test.

Exclusive to OAL

= Ref oil required.

= Diamond Paid upgrade option

Example ReportBuy Me

Diesel Fuels

Fuel analysis can help detect faults and causes of:

Poor fuel efficiency

Petrol in diesel

Dirty or contaminated fuel

Damaged injectors

Failed emissions tests

Poor quality fuel supply

Blocked filters

Poor sealing

Engine knocks & Failure to start

Air leaks

As Standard all Analysis includes:

In depth & personalised human diagnostics

Our greenest low paper & reused plastic packaging

Next Working day turnarounds.

Our cog-marked bottle designed to be robust and resistant.

Unlimited access to LearnOilAnalysis.com resources

Online Access & Unlimited Training on LubeWear.com portal

Fast & Error Free Electronic Pre-Registration

Lab telephoning you for urgent/critical results

Continuous improvements to the service from your feedback

Lab Testing Includes:

Appearance and Clarity

Viscosity @ 40C

Sulphur

Contamination Elements

Standard ICP Wear Elements

Dissolved Water (ppm)

Free Water %

ISO 4406 Cleanliness

Lube Oil Contamination

Density @ 15C

Total Contamination / Sediment

FAME / Biodiesel

Acid Number. Glycerin % Recovery @ 250C & 350C Carbon Residue

Free Fatty Acids (B100) Flash Point (PMCC) Petrol in Diesel

95% Recovery Boiling Points ( IBP, Mid, FBP) Cetane Index

Cold Filter Plugging Point Cloud Point Ferrous ppm

Microbe Culture Microbial Activity Adblue / coolant in fuel

Bio-ethanol content Filter/Component/Injector Analysis Marker Dyes

Cetane Improver Additive content

Unreacted FAME Filter blocking properties

Legend:

= Standard Test.

= Ref oil required.

= Diamond Paid upgrade option

Example ReportBuy Me

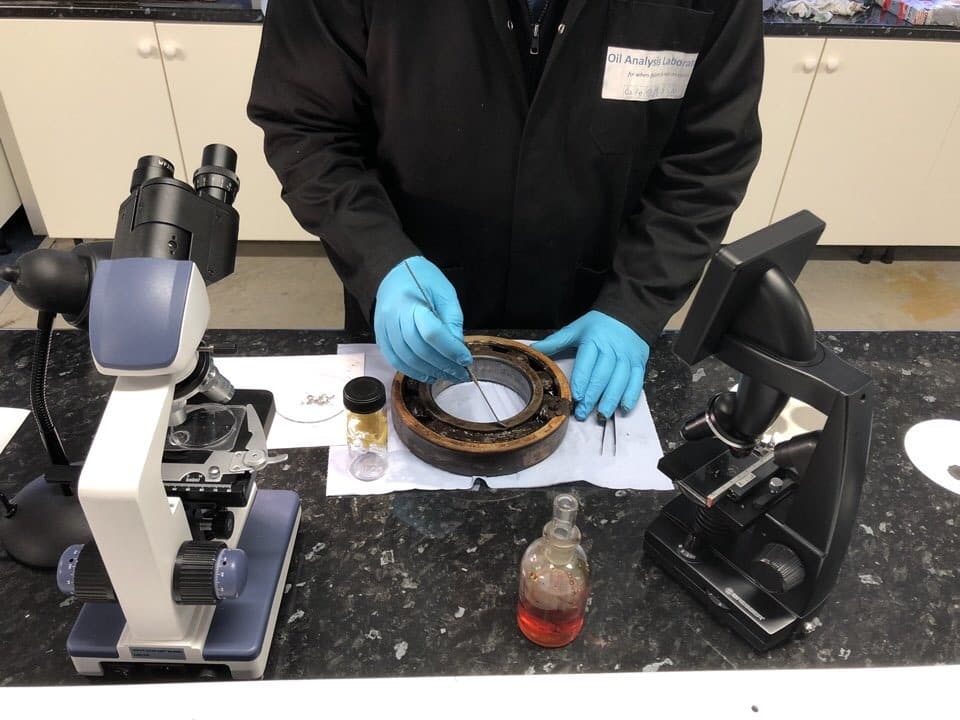

Filters, Elastomers, Injectors, Bearings & Investigative Analysis

Investigative analysis includes helping customers with specific problems with their machinery or fluids. There is no specific suite of tests as this is tailored for each sample, but it can help answer questions customers raise such as:

Wear modes & causes of failures

Cause of blocked filters

Identification of unknown materials client found in or around machinery

Seal / Rubber hardness, compatibility, swell, stretch and compression properties.

Example ReportBuy Me

Grease & Bearings

Grease analysis can help detect faults such as:

Misalignment

Under / Over-greasing

Mixing of grease types

Contaminants e.g. dirt + water

Over used lubricant / overheating

Soap and lubricant separation

As Standard all Analysis includes:

In depth & personalised human diagnostics

Our greenest low paper & reused plastic packaging

Next Working day turnarounds.

Our cog-marked bottle designed to be robust and resistant.

Unlimited access to LearnOilAnalysis.com resources

Online Access & Unlimited Training on LubeWear.com portal

Fast & Error Free Electronic Pre-Registration

Lab telephoning you for urgent/critical results

Continuous improvements to the service from your feedback

UK Return Postage to lab

Lab Testing Includes:

Appearance Photo

Grease Soap Elements

Additive Elements

Contamination Elements

Standard ICP Wear Elements

LubeWear True Wear Metal Analysis

Ferrous Debris ppm

Total Water%

Ferrography Oxidation

NLGI Grade Determination. Base Oil Viscosity

Grease bleed High temperature characteristics

Drop Point Grease separation (steel mesh)

Legend:

= Standard Test.

Exclusive to OAL

= Ref oil required.

= Diamond Paid upgrade option

Example ReportBuy Me

Gears, Axles &

Transmission Oils

Gear oil analysis can help detect faults such as:

Misalignment

Wrong oil used

Dirty, wet or otherwise contaminated oil

Gear wear

Over used or overheated oil

As Standard all Analysis includes:

In depth & personalised human diagnostics

Our greenest low paper & reused plastic packaging

Next Working day turnarounds.

Our cog-marked bottle designed to be robust and resistant.

Unlimited access to LearnOilAnalysis.com resources

Online Access & Unlimited Training on LubeWear.com portal

Fast & Error Free Electronic Pre-Registration

Lab telephoning you for urgent/critical results

Continuous improvements to the service from your feedback

UK Return Postage to lab

Lab Testing Includes:

Visual appearance & Clarity

Viscosity @ 40C

Additive Elements

Contamination Elements

Standard ICP Wear Elements

LubeWear True Wear Metal Analysis

Ferrous Debris ppm

Free Water %

Viscosity @ 100C. Viscosity Index ISO cleanliness Code

NAS CleanlinessVarnish Potential Acid Number Dissolved water ppm

Iron Type - Wear vs Corrosion OAL Condition Index

Chlorine Density Pour Point Ferrography Oxidation

Legend:

= Standard Test.

Exclusive to OAL

= Ref oil required.

= Diamond Paid upgrade option

Example ReportBuy Me

Hydraulics, Turbines &

Compressor Oils

Oil analysis can help detect faults such as:

Poor Filtration

Poor Sealing

Dirty, wet or otherwise contaminated oil

Air Entrainment

Over used, overheated or varnished oil

As Standard all Analysis includes:

In depth & personalised human diagnostics

Our greenest low paper & reused plastic packaging

Next Working day turnarounds.

Our cog-marked bottle designed to be robust and resistant.

Unlimited access to LearnOilAnalysis.com resources

Online Access & Unlimited Training on LubeWear.com portal

Fast & Error Free Electronic Pre-Registration

Lab telephoning you for urgent/critical results

Continuous improvements to the service from your feedback

UK Return Postage to lab

Lab Testing Includes:

Visual appearance & Clarity

Viscosity @ 40C

ASTM Colour

Additive Elements

Contamination Elements

Standard ICP Wear Elements

LubeWear True Wear Metal Analysis

ISO4406 Cleanliness code

SAE 4059 (NAS) Cleanliness code

Sizing: 4, 5, 6, 7, 8, 10, 12, 14, 15, 20, 21, 25, 30, 38, 50, 70 micron

Insolubles

Oxidation

Dissolved Water (ppm)

Free Water %

Viscosity @ 100C. Viscosity Index Ferrous Debris

NAS A to F codesVarnish Potential Acid Number

Iron Type - Wear vs Corrosion OAL Condition Index

Chlorine Density Pour Point Ferrography

OAL H-Foam + Foam 1,2,3 water sep D1401 and IP19 Mineral in FRF/PE

RULER/LSV & RPVOT Air release Rust resistance Air release

Oil Filterability Resistivity Flash (Open & Closed) & Fire Point

Legend:

= Standard Test.

Exclusive to OAL

= Ref oil required.

= Diamond Paid upgrade option

Example ReportNeed even more in depth analysis?

Learn About Turbine Health Checks &

Show me the enhanced suitesBuy Me

Diamond Suites - Premium Level Analysis

Call +44 7504 665 414

Email: lab@oalltd.com

Our Specialist test suites do not have a routine analysis option and are not purchased with the standard analysis kits. Instead we offer bespoke and custom suites to our customers for their specific needs. Why not contact us today to find out more about our Diamond Premium testing options?

Go BackOur Analysis includes:

Urgent Same Day Analysis

New and Product Specification Testing to international standards

Safety Testing of products

Expert Advice for solving product problems